What is a hierarchy of control? In the field of Occupational Health and Safety, a series of risk control levels allow organizations to define the desired hierarchy for their controls. When the organization identifies the existing risks in its occupational safety at the time of risk assessment. It must consider the existence of appropriate controls before such risks. In this sense, when establishing or changing existing controls, the hierarchy rule must be applied to them.

When we speak of risk control, we are referring to the fact of establishing an order of priorities when applying controls to risks in terms of health and safety at work.

Types of a hierarchy of control

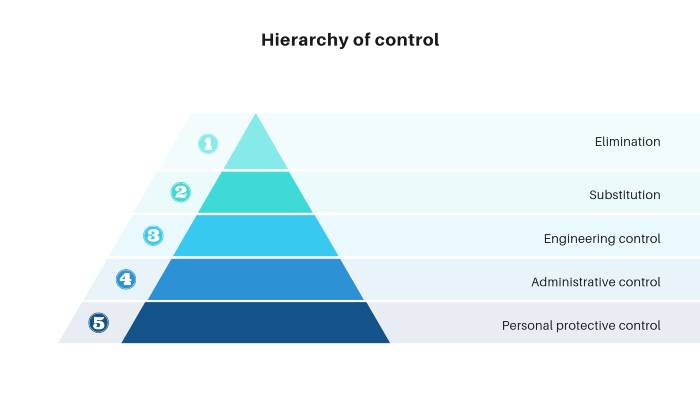

Specifically, we identified 5 levels of risk control intending to mitigate or reduce health and safety risks at work and they are the following:

- Elimination

- Substitution

- Engineering control

- Administrative control

- Personal protective equipment

Not all these controls are equally effective. For this reason, a hierarchy is established in the controls. So that the organization knows when to apply each one to achieve the objective. which is nothing more than the elimination of the risk.

The organization first evaluates the occupational hazards and analyzes whether the controls that count or are not relevant. If this is not the case, it will be necessary either to define new controls or to improve existing ones. If the organization considers it necessary to define new risk controls, we must define them following the hierarchy mentioned above.

In the first place, we will define controls that seek first to achieve risk mitigation. After that, we will define controls that can reduce the risk as much as possible and so on. The last of the control options will be the application of some PPE.

The organization can decide to apply only one of them or opt for a combination of several of them. Let’s see how to proceed when planning risk control levels.

1- Elimination:

This control of occupational risk supposes the change in the design itself to eliminate the danger at its roots. For example:

Clean up liquid spills, remove objects dropped on the floor, remove high objects that may fall, remove containers containing flammable liquids from the workplace etc.

2 - Substitution:

With this, when we do not eliminate the risks, we do achieve a reduction, for example, in an industrial process a chemical that is corrosive and toxic for workers is used. For this reason, this substance has been replaced by another that is not, which represents a lower risk and does not alter the process.

A piece of equipment produces emissions of toxic and flammable gases, due to the risk it represents. The company has decided to replace the equipment with a more recent model with a technology that avoids such emissions of dangerous gases. Replace defective equipment and tool etc.

3 - Engineering control:

Engineering controls are considered to be the installation of ventilation and extraction from dangerous atmosphere systems, interlocks, and machine protection, among guards to protect rotating parts of equipment, placement of griddles and blind flanges, placement of a cover or rail around an opening, etc.

4 - Administrative controls:

such as fluorescent signs, sirens, alarms, security procedures, equipment inspections, labelling to warn, work permits, among signs, procedures, manuals, instructions, maintenance programs, training programs, air monitoring records, authorizations for risky work, personnel rotation records etc.

5 - Personal protective equipment:

These PPE control elements, for example, safety glasses, hearing protection, harnesses, gloves, and face shields, among others. Ideals are the first three levels of this hierarchy, but not always, for cost reasons, it is possible to apply them.

Apply the criterion of good practices in the risk control process. Benefit from technical advances as a way to improve controls. Prioritize global protection over individual protection. It considers the appropriate acceptance of the control measure by the specific personnel.

Consider the need to resort to emergency plans in the event of control failures. In this sense, when faced with high-risk activities, we will adopt those actions or controls that eliminate or greatly reduce such risk. There are several standards, codes and legal requirements in this regard that help to select the best controls against certain hazards.

For more health and safety topics visit: Safety Zone

Related toolbox topic: Housekeeping toolbox